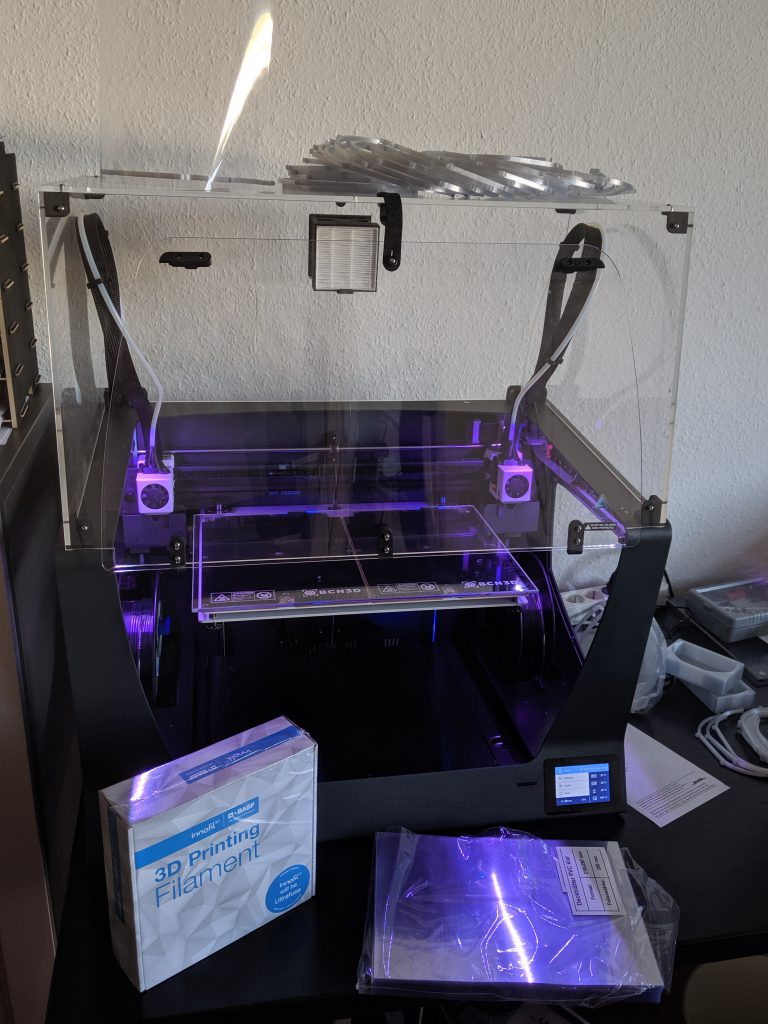

At Paratron we use Fused Filament Fabrication (FFF) type printers (BCN3D SigmaX and Anet A8) to produce parts, functional prototypes and to validate designs.

FFF offers best in class cost/performance ratio. A broad range of thermoplastic materials (e.g. ABS, but also engineering plastics such as PA or metal composites such as Ultrafuse 316L) can be fed into a heated nozzle and applied in molten state on a print bed in a layer-wise fashion.

Other 3D printing technologies such as Selective Laser Sintering or photopolymer based modalities are accessed through Service Bureaus (e.g. Sculpteo)

Metal FFF is a novel technology that enables cost-effective, easy and safe production of metal parts. The material is based on Metal Injection Molding feedstocks and comprises binders and metal powders. Standard FFF printers can be used to produce so called green parts which need to be debound and sintered to yield full metal parts. Densities similar to metal injection molded parts are possible (typically 97%). The density greatly influences the mechanical properties which need to be taken into account when designing a part for a specific application.